1. Achieve direct printing on socks Different

from heat transfer printing, easier process

save time ,save labor, direct to socks printing

make sure the ink is well abosrbed into the yarn

not just stay in the surface

2.The printed pattern is without any voids

white line 360 degree printing, no visual

break in the printed artwork

3. Adopt epson high resoultion printhead

Deliver extrodinary performance and details

perfectly present gradinet effect

4. Solid machine body Solid machine body

decreases the shaking during printing

to make sure the printing quality

5. printhead height adjustable Adjust

printhead height according to the different socks thickness

Model

Print Head

Printing size

Speed

Resolution

Ink type

File type

Color mode

Power requirement

Dimension (L/W/H)

Operating environment

StableGlobal top-end industrial print head. Anti-scratch printhead protection design. Industrial ink supply system.

StableGlobal top-end industrial print head. Anti-scratch printhead protection design. Industrial ink supply system. User-friendlyIntelligent constant-moisturizing capping system and Creative auto-wiping printhead self-cleaning system. Powerful unattended production mode. Tension-adjustable continuous winding/unwinding control technology. Separate media entry unit (Optional): Support 10,000 meters jumbo roll with Maximum roll diameter of 1.2m. Adjustable vacuum system:The vacuum power can be adjusted by software for different printing media, so the media flatness is optimized to improve the accuracy of ink drop point.

User-friendlyIntelligent constant-moisturizing capping system and Creative auto-wiping printhead self-cleaning system. Powerful unattended production mode. Tension-adjustable continuous winding/unwinding control technology. Separate media entry unit (Optional): Support 10,000 meters jumbo roll with Maximum roll diameter of 1.2m. Adjustable vacuum system:The vacuum power can be adjusted by software for different printing media, so the media flatness is optimized to improve the accuracy of ink drop point. FastUp to 360 ㎡/hr Printing Speed.

FastUp to 360 ㎡/hr Printing Speed. Powerful service networkCreate value for customers, Homer contributes to your success with comprehensive services and business mode consulting. Professional engineers awaiting, to help solve your problems.

Powerful service networkCreate value for customers, Homer contributes to your success with comprehensive services and business mode consulting. Professional engineers awaiting, to help solve your problems.Dye sublimation is widely used in many areas, which is also popular in textile printing. Easy operation as well as a good performance is the essential part of the process, when combined with digital printing. Infinite possiblities of patterns becomes possible.

Industrial ink supply system: Peristaltic-pump ink supply+Automated negative pressure monitoring &adjusting system+ Efficient ink degassing

Industrial ink supply system: Peristaltic-pump ink supply+Automated negative pressure monitoring &adjusting system+ Efficient ink degassing Tension-adjustable continuous winding/unwinding control technology

Tension-adjustable continuous winding/unwinding control technologyApplicable for advertising,broader range of alternatives.

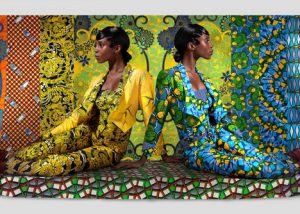

Dye sublimation transfer

Dye sublimation transfer Home textile direct printing

Home textile direct printing Direct-to-textile signage

Direct-to-textile signageDye sublimation is widely used in many areas, which is also popular in textile printing. Easy operation as well as a good performance is the essential part of the process, when combined with digital printing. Infinite possiblities of patterns becomes possible.